Aircel ABP Series / Heated Blower Purge Desiccant Dryer

The Aircel Programmable Controller (APC) and Energy Management System (EMS) is standard on the new Aircel ABP Series. This energy-saving control reduces purge air and optimizes dryer performance by monitoring the dry air outlet dew point with a sensor. This control panel automatically adjusts the regeneration cycle maintaining dew point and extending the drying cycle. Switching is less frequent, reducing dryer maintenance and fully utilizing desiccant capacity. This addition will improve reliability and performance while sustaining a constant dew point. The end result is an overall purge reduction and significant energy savings.

The Aircel ABP Series utilizes the Allen Bradley MicroLogix 1100E PLC Controller for automatic control and flexible programming. This addition sets a higher standard of configurations and capabilities that exceeds other blower purge dryers in the market. With built-in Ethernet connection, you can access, monitor and program from any available connection. An embedded web server is also included to configure controller data easily on a web page.

Features

- Desiccant Media & Fill Port

- Thermal Relief Valves

- Regulated & Filtered Pilot Air

- Outlet Dew Point Sensor

- Desiccant Media & Fill Port

- ASME Carbon Steel Vessels

- NEMA 4 Immersion Heater

- Aircel Programmable Controller (APC)

- High-Efficiency Blower

- High Voltage Enclosure (Optional)

- Rugged Steel Frame

- Pressure Control

- Pilot Solenoid

- High Temperature Tubing

- Purge Exhaust Mufflers

- Angle-Body Purge Exhaust Valve

- High Performance Butterfly Valve

- Desiccant Drain Port

- Tower Pressure Gauges

- Mounted Pre & After Filter

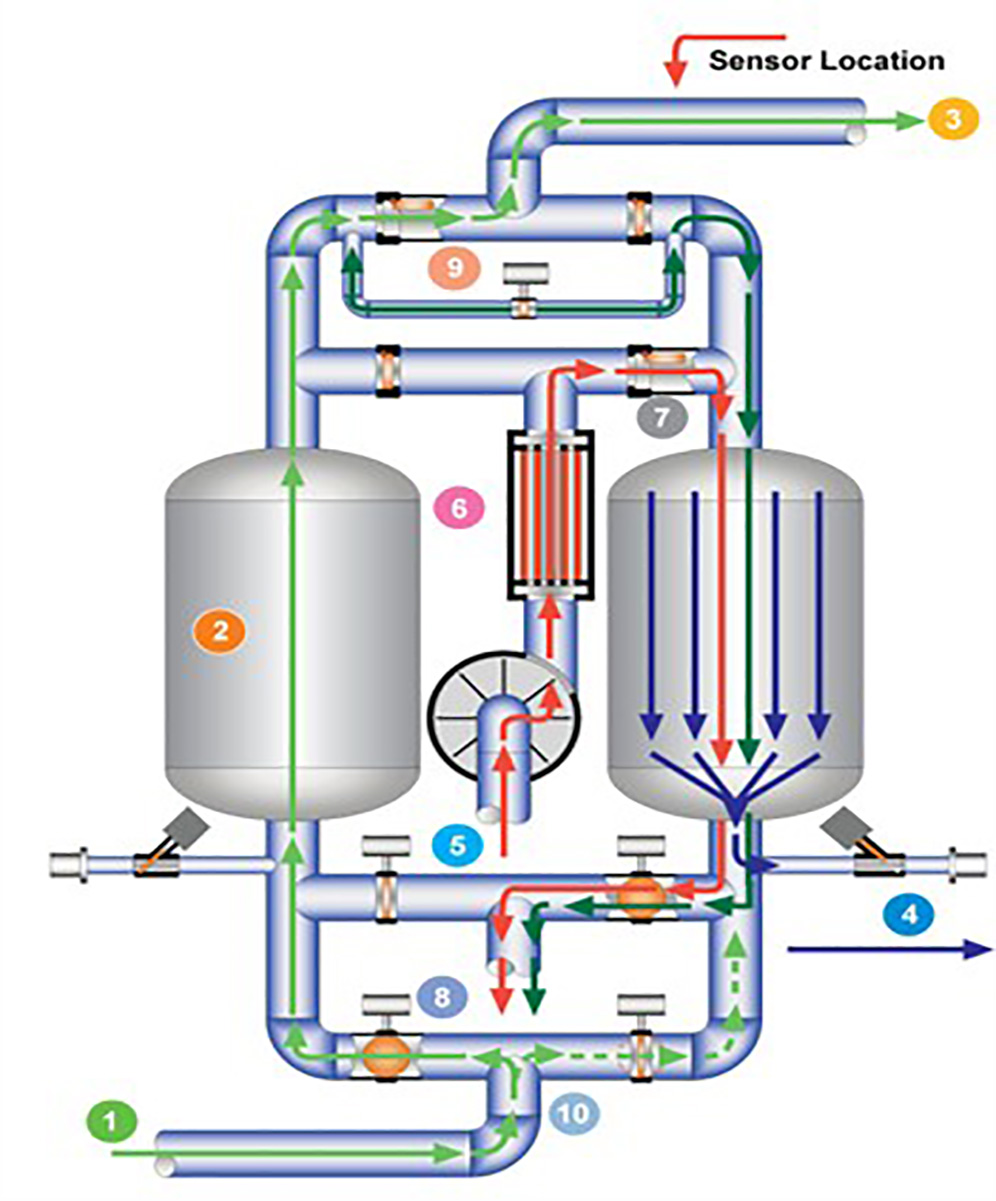

1 - Pre-filtered wet compressed air enters the bottom of the on-line vessel.

2 - Compressed air passes upward through the desiccant bed; moisture is removed, lowering the dew point to -40º F.

3 - Dry compressed air exits the top of the vessel and flows downstream to the after-filter, monitored constantly via standard dew point sensor. This EMS feature extends the drying period until the target dew point occurs. This greatly reducing energy costs.

4 - Prior to regeneration, saturated online vessel goes offline and depressurizes to ambient through an angle seat valve and muffler.

5 - After the off-line vessel has depressurized, a blower draws in ambient air for regeneration.

6 - This air passes thru an immersion heater, check valve, and enters top of regenerating vessel.

7 - As the hot ambient air passes downward through the desiccant bed, water molecules are released from the surface of the desiccant.

8 - Hot regeneration air passes through a butterfly valve and exhausts to atmosphere. Heating phase may terminate early due to low load conditions; this energy savings is automatically passed onto the customer and allows for earlier cooling process to begin.

9 - At the end of the heating phase of the cycle, the desiccant bed, although regenerated, remains hot. The temperature of the bed must be lowered to reduce dew point and temperature spikes in the process air when the bed goes back on-line. This is accomplished by allowing a slipstream of dry process air, controlled by an automatic valve, to flow from the on-line vessel into the off-line vessel. This slipstream is also used to repressurize the offline vessel after it has been cooled placing the unit into standby. The EMS control continues to save by extending the drying period through outlet dew point monitoring until the target dew point is reached.

10 - Unique to the Aircel ABP is our parallel running period 10 minutes after vessel switchover. During this period, the incoming flow of wet compressed air is directed through both vessels. This step further reduces the dew point and temperature spikes associated with heated dryers. This parallel cooling mode requires no purge air.

| Model | Capacity1 (scfm) | Connection (in.) | Heater kW | Blower HP | Full Load Amps | Dimensions (in.) | Weight (lbs) |

||

|---|---|---|---|---|---|---|---|---|---|

| L | W | H | |||||||

| ABP-800 | 800 | 3” FLG | 18 | 5 | 34 | 93 | 50 | 95 | 3500 |

| ABP-1000 | 1000 | 3” FLG | 22 | 5 | 39 | 95 | 52 | 100 | 4500 |

| ABP-1200 | 1200 | 3” FLG | 27 | 7.5 | 48 | 98 | 60 | 100 | 5100 |

| ABP-1400 | 1400 | 3” FLG | 32.5 | 10 | 55 | 100 | 70 | 110 | 6800 |

| ABP-1600 | 1600 | 4” FLG | 37 | 10 | 60 | 115 | 71 | 112 | 7500 |

| ABP-2000 | 2000 | 4” FLG | 45 | 10 | 70 | 117 | 73 | 112 | 8850 |

| ABP-2500 | 2500 | 4” FLG | 52 | 15 | 86 | 119 | 73 | 122 | 9800 |

| ABP-3000 | 3000 | 6” FLG | 64 | 15 | 101 | 138 | 79 | 122 | 12800 |

| ABP-3500 | 3500 | 6” FLG | 78 | 15 | 119 | 161 | 82 | 132 | 13500 |

| ABP-4000 | 4000 | 6” FLG | 90 | 15 | 140 | 163 | 86 | 135 | 15600 |

| ABP-5000 | 5000 | 6” FLG | 110 | 20 | 165 | 174 | 93 | 147 | 17900 |

| ABP-6000 | 6000 | 8” FLG | 120 | 20 | 178 | 174 | 93 | 147 | 22377 |

| ABP-7000 | 7000 | 8” FLG | 140 | 20 | 203 | C/F | C/F | C/F | 26852 |

| ABP-8000 | 8000 | 8” FLG | 160 | 25 | 235 | C/F | C/F | C/F | 31327 |

| ABP-10000 | 10000 | 8” FLG | 200 | 30 | 291 | C/F | C/F | C/F | 44755 |

Fill the form below for our sales expert to contact you to discuss about your requirement. We respect your privacy and will not share your personal information with others.