Aircel AHLD-E Series / Heatless Regenerative Desiccant Dryer

The Aircel AHLD E-Series is a fully automatic Dual Tower Heatless Regenerative Compressed Air Dryer with an integrated Energy Management Purge Reduction System. The PLC Controller provides complete reliable control of the system with text description of each step in the sequence of operation. The E-Series reliable operation and robust valving, requires no user adjustment and virtually no user maintenance. Our precision engineered components and design deliver outstanding service life and operational durability. Aircel has the experience, engineering and manufacturing capabilities to continuously develop dryers with the highest quality performance.

The Aircel Programmable Controller (APC) and Energy Management System (EMS) is standard on the AHLD. This energy-saving demand cycle reduces purge air and optimizes dryer performance by monitoring the moisture fast and early in the middle portion of the tower desiccant bed. This control panel automatically adjusts the regeneration cycle maintaining dew point and extending the drying cycle. Switching is less frequent, reducing dryer maintenance and fully utilizing desiccant capacity. This addition will improve reliability and performance while sustaining a constant dew point. The end result is an overall purge reduction and significant energy savings.

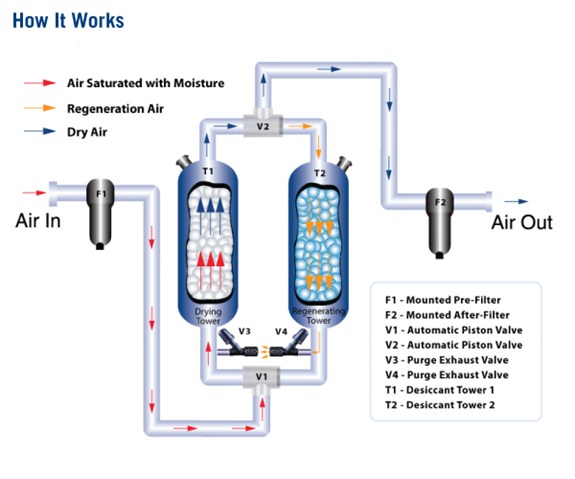

Moisture saturated compressed air enters the coalescing pre filter (F1) where aerosols are coalesced then drained via an automatic drain system. The moist water vapor-laden inlet air free of liquid water flows to the inlet of the dryer through the APV (Automatic Piston Valve) (V1) which diverts the inlet air to one of the towers, in this example tower (T1). Air flows upward through the adsorbent bed removing the moisture vapor, the dried airflow exits the tower through the outlet APV valve (V2) flowing to the outlet particulate after filter (F2) which removes particulates from the air stream. Clean and dry air now flows to the process air distribution system.

| Model | Capacity1 (scfm) | Connection | Dimensions (in.) | Weight (lbs) | ||

|---|---|---|---|---|---|---|

| H | L | W | ||||

| AHLD-70 E | 70 | 3/4” NPT | 73 | 26 | 22 | 410 |

| AHLD-100 E | 100 | 1” NPT | 75 | 30 | 24 | 490 |

| AHLD-150 E | 150 | 1” NPT | 75 | 30 | 24 | 560 |

| AHLD-200 E | 200 | 1-1/2” NPT | 85 | 34 | 24 | 800 |

| AHLD-250 E | 250 | 1-1/2” NPT | 85 | 34 | 24 | 870 |

| AHLD-300 E | 300 | 1-1/2” NPT | 86 | 46 | 30 | 990 |

| AHLD-350 E | 350 | 2” NPT | 87 | 46 | 30 | 1020 |

| AHLD-450 E | 450 | 2” NPT | 87 | 46 | 30 | 1140 |

| AHLD-500 E | 500 | 2” NPT | 89 | 50 | 30 | 1250 |

| AHLD-600 E | 600 | 2” NPT | 89 | 50 | 30 | 1450 |

| AHLD-750 E | 750 | 2” NPT | 90 | 50 | 30 | 1850 |

| AHLD-1000 E | 1000 | 3” FLG | 94 | 66 | 40 | 2800 |

| AHLD-1250 E | 1250 | 3” FLG | 98 | 70 | 40 | 4000 |

| AHLD-1500 E | 1500 | 3” FLG | 99 | 70 | 40 | 4600 |

| AHLD-2000 E | 2000 | 4” FLG | 109 | 93 | 50 | 5800 |

| AHLD-2500 E | 2500 | 4” FLG | 115 | 112 | 60 | 6400 |

| AHLD-3000 E | 3000 | 4” FLG | 120 | 118 | 70 | 7800 |

| AHLD-3500 E | 3500 | 6” FLG | 125 | 120 | 70 | 9600 |

| AHLD-4000 E | 4000 | 6” FLG | 128 | 120 | 75 | 10200 |

| AHLD-4500 E | 4500 | 6” FLG | 130 | 130 | 80 | 10900 |

| AHLD-5000 E | 5000 | 6” FLG | 135 | 130 | 80 | 11500 |

Fill the form below for our sales expert to contact you to discuss about your requirement. We respect your privacy and will not share your personal information with others.