Aircel VF Series / Non-Cycling Refrigerated Compressed Air Dryer

The Aircel VF Series (10 - 1,200 scfm) offers the highest efficiencies at varying flow conditions in a lightweight, compact design. No other dryer in the industry can offer the efficiency ratings achieved by the VF Series dryers in variable flow operation. VF Series dryers are built with the patented Variable Flow heat exchanger, which allows for desired dew point performance regardless of flow variations. Typically, other dryers with mechanical moisture separators lose performance as compressed airflow velocity increases or decreases substantially around the nominal design point.

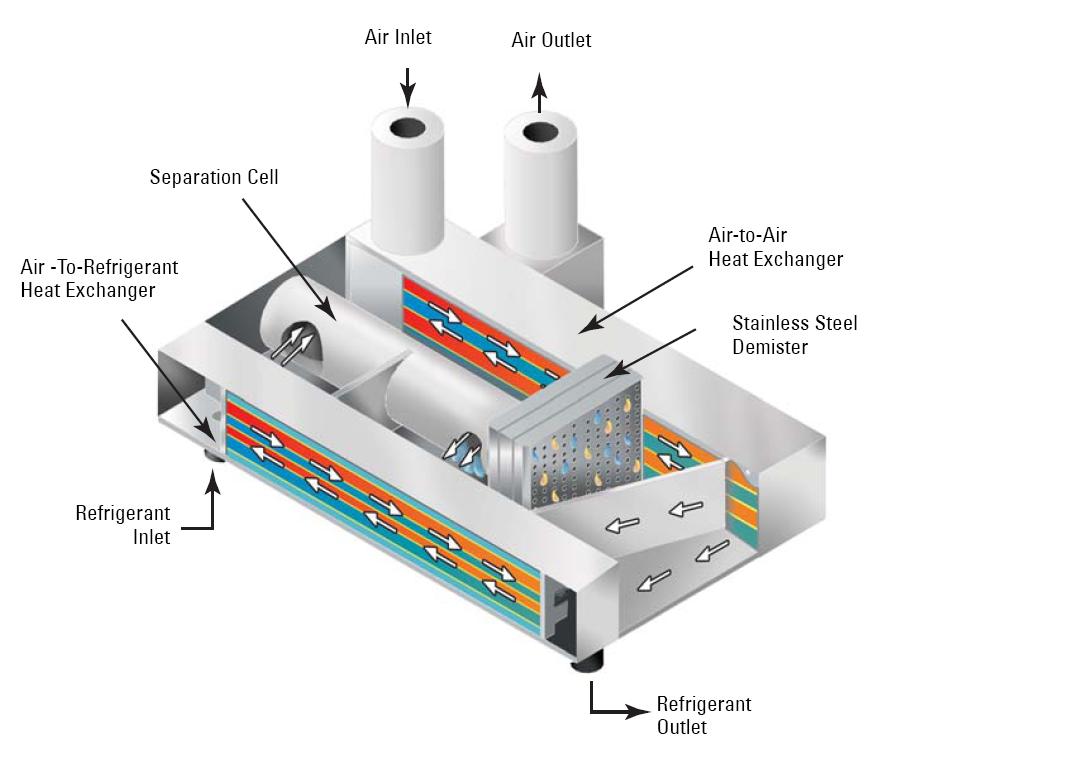

The VF Series high efficiency heat exchanger utilizes a three-step process to thoroughly remove condensed moisture from the chilled compressed air. This process provides separation efficiency in excess of 98% throughout the dryer’s entire flow range. Our VF non-cycling range is focused on reliable, constant dew point performance in all flow conditions. With its excellent heat transfer coefficients and low-pressure drop, these dryers will outperform the competition in protecting your compressed air system, machinery and tools; and will improve your manufacturing processes.

FEATURES

- Pre-cooling and reheating of compressed air for high efficiency & low energy consumption

- Stainless steel plate heat exchanger (VF-10 to VF-60)

- Aluminum block heat exchanger with integrated high efficiency separator (VF-75 to VF-1200)

- Environmentally friendly R-134a (VF-10 to VF-800) and R-404a (VF-1000 to VF-1200) refrigerant

- Refrigerant suction pressure gauge

- Refrigerant discharge pressure gauge (VF-200 +)

- Inlet pressure and temperature gauge (VF-400 +)

- Advanced scroll technology (VF-500 and up)

- External moisture separator & zero-air loss drain (VF-800 +)

- Heavy-duty industrial powder coated cabinet w/ access panel

- NEMA 1 Standard

Hot, saturated compressed air is first precooled by exiting cold air in the air-to-air heat exchanger. The precooled air then enters the evaporator where it is cooled to its final dew point. The mixture of cold air and condensation flows into the three-stage separator/mist eliminator where liquids and contaminants are reliably removed and ejected from the system via a programmable timer drain valve. The cold air is then reheated by the incoming hot air before leaving the dryer.

| Model | Capacity@ CAGI1 (scfm) |

Connection (inches NPT) |

Nominal Ref HP Installed (size) |

Air-Cooled kW (full load) |

Full Load Amps | Voltage (Standard) |

Dimensions (inches) | Pressure max. (psig) |

Weight (lbs) |

Refrigerant | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Height | Width | Depth | |||||||||||

| VF Compact Series |

VF-10 | 10 | 1/2 | 1/5 | 0.15 | 6 | 115-1-60 | 15 | 16 | 16 | 200 | 71 | R-134a |

| VF-15 | 15 | 1/2 | 1/5 | 0.15 | 6 | 115-1-60 | 15 | 16 | 16 | 200 | 74 | R-134a | |

| VF-25 | 25 | 1/2 | 1/5 | 0.15 | 6 | 115-1-60 | 15 | 16 | 16 | 200 | 76 | R-134a | |

| VF-40 | 40 | 3/4 | 1/4 | 0.24 | 7 | 115-1-60 | 15 | 16 | 16 | 200 | 78 | R-134a | |

| VF-50 | 50 | 3/4 | 1/4 | 0.60 | 7 | 115-1-60 | 15 | 16 | 16 | 200 | 80 | R-134a | |

| VF-60 | 60 | 3/4 | 1/3 | 0.86 | 11 | 115-1-60 | 15 | 16 | 16 | 200 | 102 | R-134a | |

| VF-75 | 75 | 1 | 1/3 | 0.86 | 11 | 115-1-60 | 22 | 24 | 18 | 200 | 124 | R-134a | |

| VF-100 | 100 | 1 | 1/2 | 1.33 | 16 | 115-1-60 | 22 | 24 | 18 | 200 | 138 | R-134a | |

| VF-125 | 125 | 1 | 3/4 | 1.72 | 21 | 115-1-60 | 22 | 24 | 18 | 200 | 156 | R-134a | |

| VF-150 | 150 | 1 | 3/4 | 1.72 | 21 | 115-1-60 | 22 | 24 | 18 | 200 | 162 | R-134a | |

| VF-200 | 200 | 1-1/2 | 1 | 1.98 | 12 | 230-1-60 | 30 | 36 | 25 | 200 | 240 | R-134a | |

| VF-250 | 250 | 1-1/2 | 1-1/2 | 3.10 | 5 | 460-3-60 | 30 | 36 | 25 | 200 | 332 | R-134a | |

| VF-300 | 300 | 2 | 1-1/2 | 3.58 | 6 | 460-3-60 | 30 | 36 | 25 | 200 | 345 | R-134a | |

| VF-400 | 400 | 2 | 2 | 4.85 | 9 | 460-3-60 | 45 | 34 | 45 | 175 | 567 | R-134a | |

| VF-500 | 500 | 2 | 3-1/2 | 6.53 | 12 | 460-3-60 | 45 | 34 | 45 | 175 | 582 | R-134a | |

| VF-600 | 600 | 3 | 3-1/2 | 6.76 | 13 | 460-3-60 | 45 | 34 | 45 | 175 | 598 | R-134a | |

| VF-800 | 800 | 3 | 5 | 6.61 | 15 | 460-3-60 | 48 | 38 | 54 | 175 | 790 | R-134a | |

| VF-1000 | 1000 | 3 | 5 | 6.84 | 17 | 460-3-60 | 48 | 38 | 54 | 175 | 800 | R-404a | |

| VF-1200 | 1200 | 3 | 6 | 10.98 | 20 | 460-3-60 | 48 | 38 | 54 | 175 | 852 | R-404a | |

Fill the form below for our sales expert to contact you to discuss about your requirement. We respect your privacy and will not share your personal information with others.