Aircel BHD Series / Breathing Air System

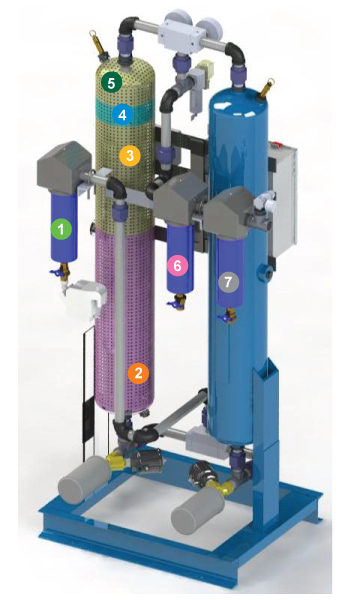

The Aircel BHD series is fully automatic breathing air system that utilizes a unique dual tower regeneration process. The BHD Series purifies compressed air to breathable air by removing a variety of contaminants including dust, dirt, water, oil, hydrocarbon vapor and dangerous levels of carbon monoxide.

The Aircel Programmable Controller (APC) provides complete control of the system with text description of each step in the sequence of operation. A high quality Carbon Monoxide (CO) Monitor is standard providing constant sensing of CO concentrations to ensure the safety of all users. The BHD Series has robust valving and includes high quality coalescing pre-filter, activated carbon after-filter, and a particulate final-filter mounted as a standard feature.

The BHD Series achieves a unique seven stage purification process without the addition of a 3rd purification vessel that is required and utilized by many competitive designs.

FEATURES

- Compact digital Carbon Monoxide (CO) monitor/alarm

- Efficient electronic purge reduction with EMS

- Mounted filtration: pre-filter, carbon after-filter and final-filter

- APC protected with a NEMA 4 electrical steel enclosure

- LED tower operation display indicating sequence of operation

- Automatic piston valve (inlet/outlet) with 10 year longevity

- Purge exhaust mufflers for quiet operation

- Angle-body purge exhaust valve with 10 year longevity

- Tower pressure gauges with large easy-to-read 3.5” display

- Counter-current regeneration, upflow drying, and downflow depressurization

- Easy access to fill and drain ports for media replacement

- ON/OFF switch and power ON light

- Red alarm strobe light

- Tower failure to switch alarm

Stage 1: Inlet Particulate & Coalescing Pre-Filter: The pre-filter removes particulates, water aerosols, and oil mist content efficiently. The pre-filter is equipped with a differential pressure indicator and a Zero-loss automatic condensate drain valve.

Stage 2: 13X Molecular Sieve: The inlet portion first layer of the adsorbent media filled in the towers is 13X molecular sieve to remove contaminants such as volatile organic compounds, acid forming gases, base gases and moisture.

Stage 3: Activated Alumina: This layer of activated alumina removes moisture to a dewpoint of -40°F and below at line pressure.

Stage 4: Carulite Catalyst: The catalyst layer is used to convert carbon monoxide to carbon dioxide and to oxidize residual hydrocarbon vapors.

Stage 5: Activated Alumina: This final layer of activated alumina is installed at the top of the towers to remove residual contaminants.

Steps 2-5: The towers adsorb and regenerate alternatively. The regeneration of this unique multi-layer adsorbent media and catalyst arrangement typically extends its life under normal conditions to three to five years. The control system sequence is monitored by a standard fail to switch system using pressure transducers and alarms when the system does not function properly.

Stage 6: Activated Carbon After-Filter: The activated carbon contained in the filter element assures a residual oil vapor content below 0.003 ppm. The filter is equipped with a manual ball valve.

Stage 7: Sub-Micron Final-Filter: The final-filter efficiently removes fine aerosols and particulates generated in the system. The filter is equipped with a differential pressure indicator and manual ball valve.

The outlet air is monitored by a high quality Carbon Monoxide (CO) analyzer and triggers an alarm when a preset level is reached.

| Model | Inlet Capacity1 (scfm) |

Outlet Capacity1 (scfm) |

Inlet/Outlet Connection (NPT) |

Dimensions (inches) | Weight (lbs) |

Voltage (Standard) |

||

|---|---|---|---|---|---|---|---|---|

| H | L | W | ||||||

| BHD-50 | 50 | 40 | 1/2” NPT | 73 | 30 | 24 | 475 | 115V/60 HZ |

| BHD-80 | 80 | 64 | 3/4” NPT | 76 | 36 | 26 | 550 | 115V/60 HZ |

| BHD-100 | 100 | 80 | 1” NPT | 76 | 36 | 29 | 675 | 115V/60 HZ |

| BHD-150 | 150 | 120 | 1” NPT | 84 | 39 | 29 | 850 | 115V/60 HZ |

| BHD-200 | 200 | 160 | 1-1/2” NPT | 85 | 40 | 32 | 975 | 115V/60 HZ |

| BHD-250 | 250 | 200 | 1-1/2” NPT | 86 | 51 | 36 | 1150 | 115V/60 HZ |

| BHD-300 | 300 | 240 | 1-1/2” NPT | 86 | 51 | 36 | 1250 | 115V/60 HZ |

| BHD-350 | 350 | 280 | 2” NPT | 88 | 51 | 36 | 1350 | 115V/60 HZ |

| BHD-450 | 450 | 360 | 2” NPT | 90 | 55 | 43 | 1550 | 115V/60 HZ |

| BHD-500 | 500 | 400 | 2” NPT | 90 | 55 | 43 | 1750 | 115V/60 HZ |

| BHD-600 | 600 | 480 | 2” NPT | 92 | 55 | 43 | 2050 | 115V/60 HZ |

Fill the form below for our sales expert to contact you to discuss about your requirement. We respect your privacy and will not share your personal information with others.